How does the shield machine work? Let’s hear what the experts say.

Hoisting site

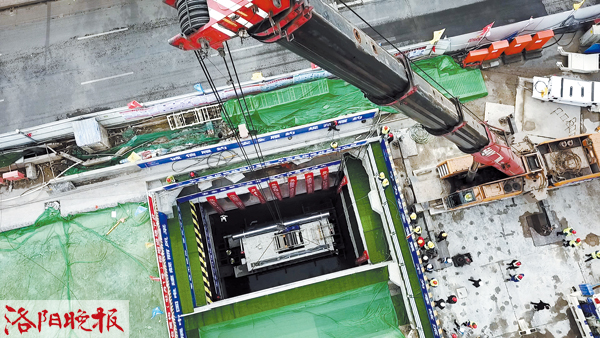

Yesterday, the first shield machine component of the subway project in our city was hoisted down at Shijiawan Station, and the mysterious underground space and shield machine component were officially unveiled. In order to satisfy your curiosity, the reporter asked the experts from the 11th Bureau of Hydropower of the contractor to reveal the secret for you.

The assembly goes down smoothly.

Look at the changes of Shijiawan Station

The appearance of Shijiawan Station is very different now: the construction workers can directly enter the underground structure space through a section of steel stairs, and the design prototype of the two underground floors has emerged.

There will be a ticket hall and an entrance and exit in the basement in the future. At present, the construction of the top cover plate has not been completed, and several large and small openings are reserved for transporting construction materials.

The second floor underground is the subway operation area, and two circular tunnels on the wall will be used for subway driving in the future. From the ground to here, the drop is 16 meters, and the shield machine trolley was hoisted from a height of nearly 6 stories. A track has been paved towards the tunnel entrance, which is for the shield machine.

Main control room of No.1 trolley

Look at the composition of shield machine

Shield machine consists of shield body, cutter head, connecting bridge, screw machine, trolley and other components, of which the largest one is trolley. A group of shield machine equipment has 6 trolleys, each trolley is nearly 11 meters long, and it is 64 meters long after being assembled. Imagine that the shield machine is actually like dragging a train behind it during the excavation process.

The trolley is hollow, and it is internally equipped with 5 muck trucks, 1 mortar truck and 2 segment trucks. The track of the shield machine is a double track, the outer track is 2080 mm wide, and it is driven by a trolley; The inner rail is 970 mm wide and is driven by a muck truck. The reason for this design is that it has a lot to do with the principle of shield tunneling.

The nose is responsible for excavating the underground soil layer, and the generated muck is transported to the muck truck by conveyor belt. Once the excavation space is large enough, the shield machine will stick the segment to the tunnel wall, just like tiling. The segment is 1.5 meters wide, that is, each tunneling step is 1.5 meters wide, which is professionally called a ring. The first ring is composed of six segments, and it takes about 30 minutes to excavate each ring, resulting in nearly five cars of muck, which is why a group of shield machine equipment is equipped with five muck trucks. Mortar truck is used to water the gaps between segments. Due to the special geological conditions in our city, it may take only one day to excavate the Seventh and Eighth Ring Roads. The double-track arrangement can ensure that multiple processes can be completed on a smaller working surface.

On the function of shield machine trolley

Each trolley has different functions, including cable storage cabinet, sewage treatment system, air storage drum, circulating water pipe drum, belt conveyor driving motor, etc. For example, the large pipeline with a diameter of 1 meter on the trolley is the air supply barrel, which is responsible for conveying air to the tunnel; Coiled pipes on the trolley are water supply, water outlet and sewage pipes, which play the role of cooling the equipment during tunneling; There is also a toilet on trolley 5.

The "brain" of the whole shield machine is on the No.1 trolley. The whole tunneling process is completed by machinery. There are only two drivers in the main control room. The main driver is responsible for the operation and the assistant driver is responsible for recording the data. The main control room is a narrow space with dozens of buttons inside, which controls all related equipment of the shield machine. Three LCD screens, one is responsible for the accurate positioning of the shield machine, which is calibrated every 10 seconds. Once the shield machine deviates from the track, it will give an alarm, and the measurement unit is accurate to millimeters; One is responsible for data monitoring of all equipment; One is used to watch the monitoring video. The whole shield machine is equipped with six monitoring devices, and the driver can clearly understand the operation of each area in the main control room.

Next, the city rail company plans to hold an open day for subway citizens, when you may have the opportunity to visit the subway construction site. Please pay close attention to the related reports in the Evening News. (Luoyang Evening News reporter Lian Wei correspondent Yan Yansong Ma Wei/reporter Zhang Bin/map)